40 seconds to discover how the new CUPRA Formentor is produced

40 seconds to discover how the new CUPRA Formentor is produced

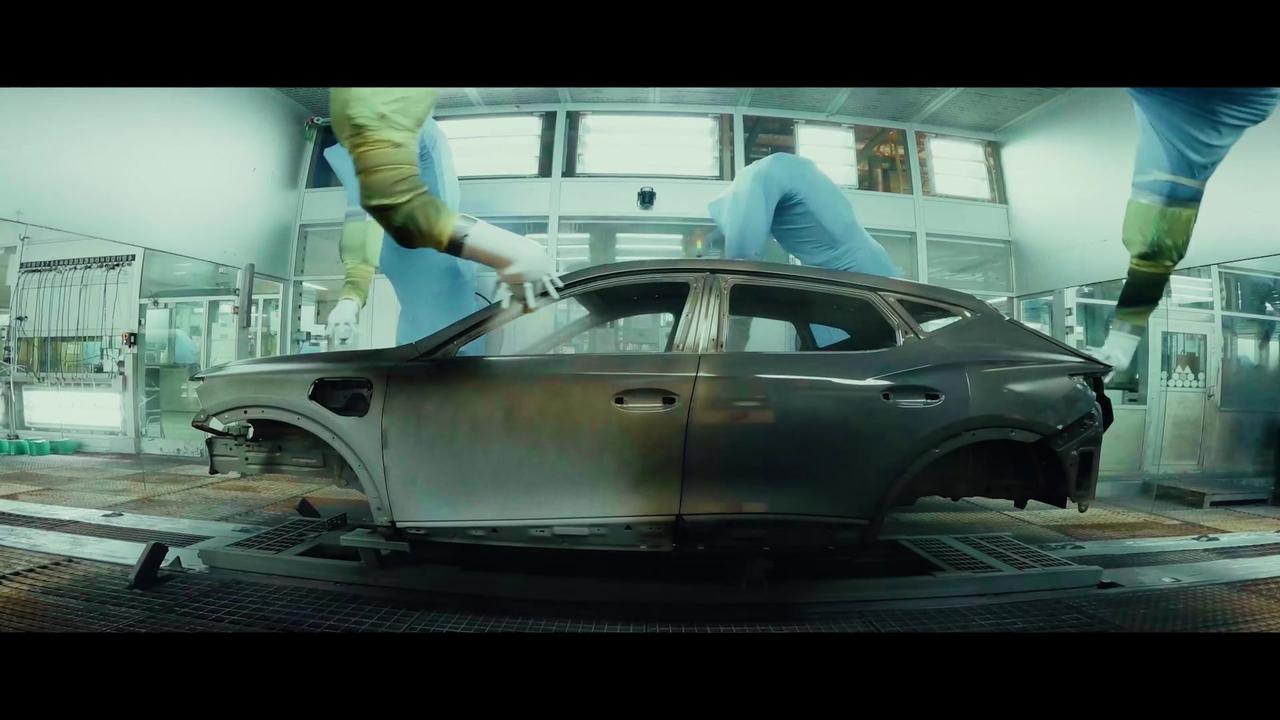

Something's changed at the Martorell plant's assembly line: the new Matrix LED three-triangle eye signature makes its appearance for the first time, while the exclusive shades Century Bronze Matt and Enceladus Grey Matt fill the paint shop with new hues of colour.

CUPRA’s design obsession is taking shape with the start of production of the new CUPRA Formentor and CUPRA Leon, which will begin distribution in the third quarter of 2024.

Designed, developed and manufactured in Martorell, the CUPRA Formentor is the brand’s best-seller, recording more than 347,000 units since its launch in 2020.

Now, revamped, it has already become an icon.

Check out its production process captured in this 40-second video.

The CUPRA Formentor’s success story is also that of more than 4,000 employees involved in the production of its restyled version.

A new car rolls off the line every 69 seconds in a dynamic, meticulous process in which every detail is analysed and reviewed to ensure maximum quality.

In fact, several innovative tools such as deep learning and top-notch digitalised systems have been implemented in its production in a further step towards the transformation of the plant.

Among these innovations is the Prüfer Digital, an automatic station equipped with an artificial vision system that controls the presence, position and condition of different parts mounted in the vehicle, with more than 60 simultaneous control points that focus on both mechanics and wiring.

Also playing an essential role is the Smart Plug system, a technology used in the production process of the CUPRA Formentor and the CUPRA Leon to deal with the assembly of more than 90 electronic control units.

This is done through remote production, automatically starting up all the control units of up to 45 cars at a time.

But the biggest innovation is the new KTL Oven, the first 100% electric transversal oven in the entire Volkswagen Group.

It’s involved in the paint-drying process, providing an anti-corrosion layer, and takes up 42% less space than a conventional oven, thanks to a reduction in length.

It also reduces energy consumption by up to 25%.